The industry of plastics has vastly enhanced and advanced lately. Rotational molding is really a distinctive and well-known way of producing plastic-type material goods that has been gaining in popularity over the years. Rotomolding can be a production procedure that employs heating and rotation to create hollow plastic elements. Rotational molding allows for the creation of Rotomolding items that would be impossible to create using other producing methods. With this blog post, we are going to consider a close look at the art of making plastic material products through rotomolding.

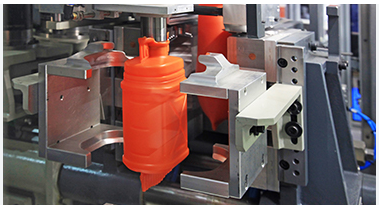

The whole process of rotomolding starts off with the flowing of plastic material resin in a mildew. The mildew is going to be heated and rotated in several directions to ensure a much heat circulation. The plastic material inside the mildew melts and moves in the preferred model of the product, generating a hollow part. When the plastic material has cooled and solidified, the product is removed through the mildew which is prepared for doing touches.

One benefit of rotomolding is it can create intricate and complex designs with relative relieve. Rotational molding is great for developing components with constant walls thicknesses, which is actually a vital element in making sure that the merchandise maintains its structural dependability. Each step from the production approach is closely monitored to ensure good quality and reliability in the closing product.

All the different products manufactured through rotational molding is considerable. Rotomolding creates pieces that range between tiny vehicle elements to sizeable storage tanks, playground devices, and even kayaks. The flexibility of rotational molding, combined with its ability to create elements with various sizes and shapes, made it a beautiful solution in the manufacturing business.

An additional benefit of rotomolding is its ability to create merchandise with multiple-layer building. This method permits rotomolders to produce things with special surface finishes, more energy, as well as other attributes how the product may need. Multiple-layering also makes it possible for items to get designed to distinct demands, such as those necessary for harmful components.

Rotomolding is definitely an eco-friendly manufacturing process. The plastic-type resins used at the same time are 100% recyclable, producing rotational molding an environmentally friendly approach to manufacturing. This feel puts the merchandise in line with the rounded economic climate vision.

In a nutshell:

In In a nutshell, rotational molding is definitely an innovative, cost-effective, and eco-warm and friendly manufacturing procedure that is taking the plastic-type material merchandise sector by hurricane. This method’s versatility permits producers to make plastic-type material merchandise with various forms, dimensions, and wall structure thicknesses that satisfy the distinct requirements in their consumers. Rotational molding could also be used to generate goods with multi-layered building, offering customers with innovative and tailored alternatives. With the increasing pattern towards eco-pleasant methods and sustainability, rotomolding will definitely be around for several years into the future.